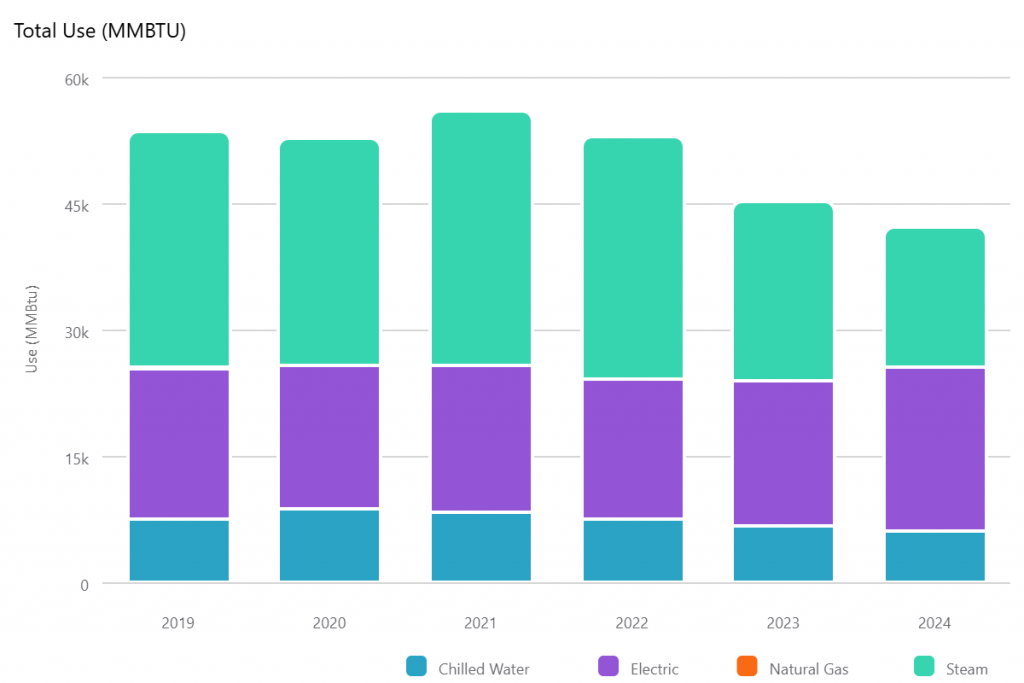

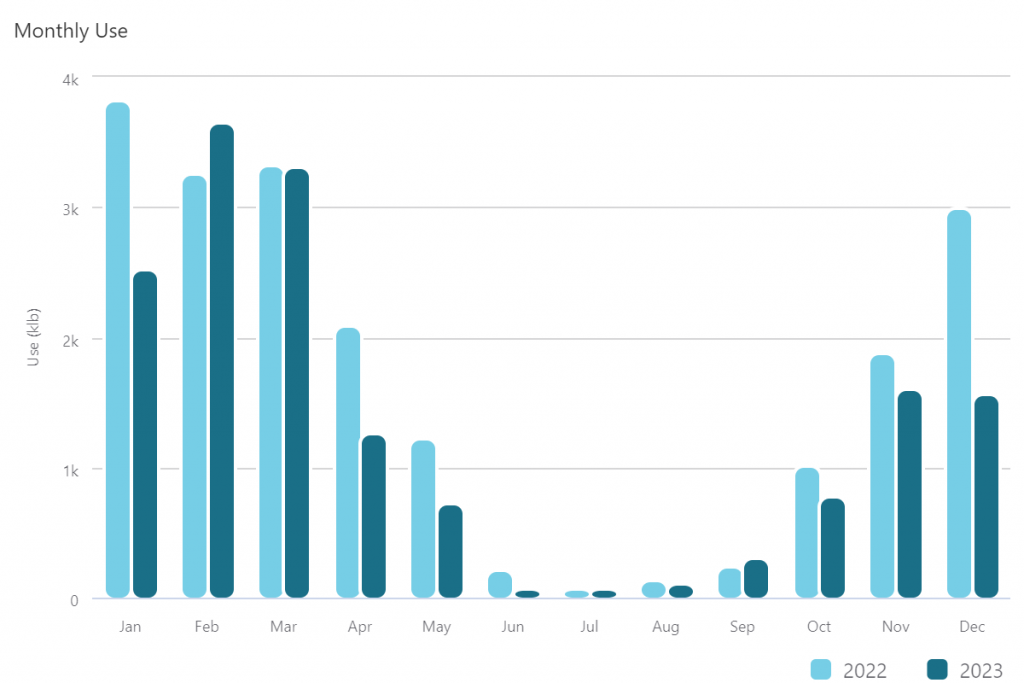

In 2021 and 2022, an energy recovery loop was added to the laboratory exhaust and chillers were reconfigured to operate in heat recovery mode. The upgrades have resulted in a 25% reduction in steam use in 2023 and a 500 MTCO2e annual emissions reduction.